Creating a Mark Twain Funko Pop

27 June 2020 • by Bob • Projects

I will admit to having a few Funko Pop characters adorning the shelves of my office. Some of the characters are from my favorite rock bands, others are from popular TV shows, and several are from history. However, there is one historical character who has been one of my favorite authors since childhood, though he has been sadly overlooked in the Funko Pop universe: Mark Twain.

Mark Twain is one of America's most acclaimed humorists and novelists, and for that reason I found it perplexing that the makers of Funko Pop hadn't immortalized his likeness, despite creating likenesses of other popular literary figures from history like Edgar Alan Poe, Stephen King, Dr. Suess, Leonardo da Vinci, etc.

I was lamenting Funko Pop's oversight of Mark Twain to my oldest daughter one day, and I mentioned that it wouldn't take much for the makers of Funko Pop to create a Mark Twain character since they already make Albert Einstein... if they kept the head from Einstein, all they would need was a body in a white suit. My daughter remarked that they could use the body of Colonel Sanders, so I quickly photoshopped what that would look like.

My digital prototype looked like it would work, and since I had already seen people's demonstrations for swapping the heads between bodies of Funko Pop characters, I decided that I would make my prototype a reality.

My first step was to purchase the Albert Einstein and Colonel Sanders characters.

My next step was to boil water in a shallow container, then soak the characters in the hot water for four minutes. After which, the heads were relatively easy to remove, and I was able to swap them to the other bodies.

After I finished swapping the heads and bodies, my final step was to use a sharpie pen to fully color the eyes for Mark Twain (since the Albert Einstein character's eyes were half open and looked droopy).

The completed Mark Twain looked great, though I have no idea what name I should give to the random scientist that I created from the leftover pieces.

UPDATE: This post is one of several that I had written that I later discovered had never been set to "public."

Building a Faux Fireplace for the Christmas Season

22 December 2013 • by Bob • Projects

My wife and I moved back to Arizona this past summer, and fireplaces are pretty scare here because it's generally warm for most of the winter. For example, this is the week of Christmas, and the temperatures are still in the high-60s Fahrenheit. Even though we're well into December and the rest of the country is contending with winter snow, I'm walking around in shorts and a Hawaiian shirt. So it's pretty easy to see why a fireplace isn't a selling feature for most homes in Arizona; in fact, it's often more of a nuisance.

But that being said, a lack of a fireplace has a few drawbacks during the Christmas season - and a primary downside was voiced by my wife when she recently asked, "Where are we going to hang our Christmas stockings this year?"

I have to admit - I hadn't given much thought to that question before, and I certainly wouldn't have bought a house with a fireplace just to have a place to hang stockings for a few weeks each year. Just the same, I started thinking about a way to rectify our miniscule first-world problem. My wife had travel plans that would have her out of the house for the first weekend in December, and that provided me with ample opportunity to hatch a scheme where I could do something about our stocking situation and surprise my spouse.

In case you were wondering, you read that correctly - my wife left me alone for the weekend and I spent it building a faux fireplace for her. Some guys would relish the opportunity to watch non-stop sports or action movies without having to fight for the remote, while other guys would head off to the mountains for some quality fishing or hunting. But as for me - I chose to spend my weekend wandering the aisles of my local Home Depot, Lowes, and Ace Hardware stores while picking out various parts to build something that was kind of geeky. Yup, that's just the kind of guy I am - deal with it.

Why Build a Fireplace?

First of all - why not? It's fun to build something every once in a while. ;-]

That being said, there are many different kinds of artificial fireplaces that are available on the market, but none of those met the requirements that I wanted to address:

- I didn't want the fireplace to generate any actual heat. Sure, most heat-producing artificial fireplaces will allow you to turn off the heat and simply enjoy the fake fire, but that would have denied me the opportunity to build something - and where's the fun in buying something when you can give up your weekend to build it? (Okay, I'll admit it - perhaps buying something occasionally works into your schedule a little better.)

- I wanted a fireplace that would be four-feet wide by four-feet tall, yet shallow enough to easily allow pedestrian traffic to walk past it. Several store-bought artificial fireplaces were close to those dimensions, but I usually didn't like something or other about them.

- I wanted a fireplace that could be disassembled at the end of the Christmas season so I could store it easily until next year. This was the clincher - none of the fireplaces that I looked at seemed to have a way to do this; all of the models that I looked at were designed to stay assembled forever. If a fake fireplace was on wheels, (and some were), I could push it into the garage for the next 11 months, but that would take up too much room.

In the end, building my own fireplace seemed to make the most sense to me. And if I ever decide that I'm done with it, I'm sure that I can donate to some high school's Drama Department. ;-]

Designing and Building the Fireplace

Once I had decided to build my own fireplace, the first thing that I had to do was get some fake fireplace logs. There are dozens of variations available, so that step was pretty easy - I just had to pick a set that seemed reasonable. Once I had purchased the fake logs for the fireplace, that gave me the dimensions that I would need to build the fireplace.

The next thing that I needed to do was to come up with a construction plan - which I didn't actually do. I had a general idea of what I wanted the end result to be, but it certainly wasn't a fully-formed proposal. I figured that I would wander into my local Home Depot or Lowes and wander aimlessly through the aisles until something a little more solid popped into my head, and that's pretty much what I did - with one exception: I called my dad and asked if he wanted to come along for what was undoubtedly going to be a weird construction project, and he agreed. ;-]

When we arrived at the hardware store, we headed to the lumber section, where I proceeded to explain the general concept that I had been pondering for the past few days. Between the two of us, we looked at all of our options based on the wood that was available, and we came up with a design that somewhat resembled what I had been thinking - albeit with some cool revisions.

The general design that we came up with was to create four rectangular boxes that stacked to create a square frame:

- One horizontal base box: 48-inch wide x 16-inch deep x 5-inch tall

- Two vertical left and right boxes: 9.25-inch wide x 12-inch deep x 34-inch tall

- One horizontal crown box: 48-inch wide x 12-inch deep x 9-inch tall

Since we were basically making this up as we went along, there were a few "aha" moments where we realized that our plan wasn't going to work for some reason or other, so we changed the design several times during construction. One of the great ideas that my dad came up with was to use a single 48-inch x 48-inch x 0.5-inch board as the backing for the entire project, and that worked out great; it gave support to the whole structure, and it allowed me to use textured paint it so that it looked the inside of a fireplace.

The construction was pretty straightforward - my dad and I hauled all of the raw materials to his house, where we measured the wood and we used his table saw to cut everything to size. We started by creating the base, and once we had that built, we created the left and right sides, and we followed that by creating the crown. After we put the boxes together to see what the general idea would look like, we came up with the idea of adding the facade around the crown to give it a more finished look, and we decided to add a single piece of horizontal wood as mantle, which would extend beyond the edges of the crown. Once we had all of the boxes created, I took all of the parts home where I painted everything before the final construction.

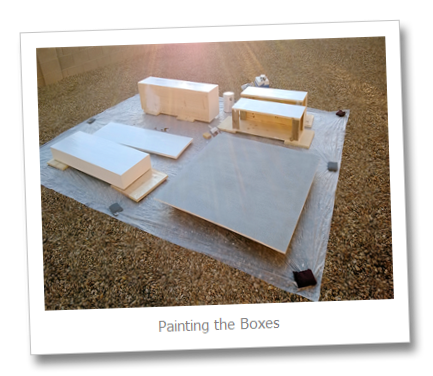

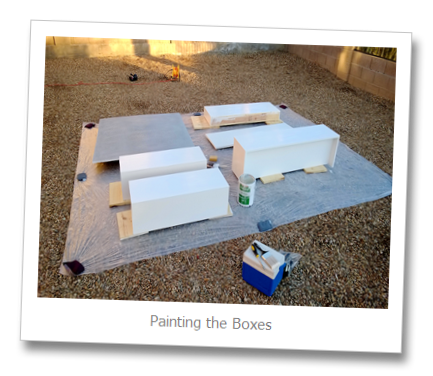

With that in mind, here are a few photographs from the latter part of the construction process:

These first few images are obviously from the painting process, and if you look closely you'll notice my ingenious use of my lead-pellet scuba diving weights to hold down the tarp. (I have no other use for those scuba diving weights since I can no longer bring those on dive trips due to TSA-induced weight restrictions, but that's another story for another day.)

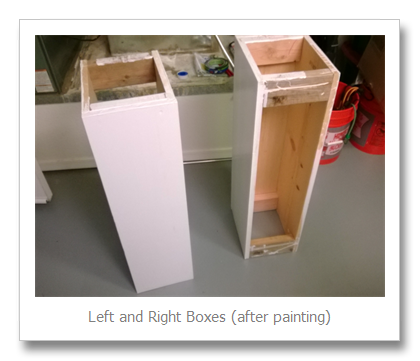

This next photo is a close-up of the front and back views for the left and right vertical boxes.

These next two photos are before-and-after shots of the partially-constructed fireplace, as seen from the back. After I had the pieces stacked correctly, I drilled holes between the different parts and secured them together with lag bolts and wing nuts.

Parts List for the Fireplace

I used several two-by-fours in this construction because the wood for the siding was fairly thin, so using two-by-fours inside the pieces allowed me to drill deeper holes and use 1.5-inch wood screws to bolt together the pieces. That being said, remember that a two-by-four is actually a 3.5-inch by 1.5-inch piece of wood, so you need to take that into account when you are measuring for wood projects. ;-]

- Backing Board:

- One 48-inch x 48-inch x 0.5-inch board (plywood is fine)

- Base Box:

- Two 48-inch x 16-inch x 0.75-inch boards (Top & Bottom)

- One 48-inch x 3.5-inch x 0.75-inch board (Front Facade)

- Two 15.25-inch x 3.5-inch x 0.75-inch boards (Left & Right Sides)

- Two 46.25-inch x 3.5-inch x 1.5-inch boards (Front Inside [behind Facade] and Back Inside); these are "two-by-fours" that are used for support

- Left-Side Box:

- One 34-inch x 9.25-inch x 0.75-inch board (Front Facade)

- Two 34-inch x 11.25-inch x 0.75-inch boards (Left & Right Sides)

- Four 7.75-inch x 3.5-inch x 1.5-inch boards (Top & Bottom Inside Front [behind Facade] and Top & Bottom Inside Back); these are "two-by-fours" that are used for support

- Right-Side Box:

- One 34-inch x 9.25-inch x 0.75-inch board (Front Facade)

- Two 34-inch x 11.25-inch x 0.75-inch boards (Left & Right Sides)

- Four 7.75-inch x 3.5-inch x 1.5-inch boards (Top & Bottom Inside Front [behind Facade] and Top & Bottom Inside Back); these are "two-by-fours" that are used for support

- Crown Box:

- Two 48-inch x 12-inch x 0.75-inch boards (Top & Bottom)

- Four 7.5-inch x 3.5-inch x 1.5-inch boards (Top & Bottom Inside Front [behind Facade] and Top & Bottom Inside Back); these are "two-by-fours" that are used for support

- One 43.5-inch x 3.5-inch x 1.5-inch board (Top Inside Back); this is a "two-by-four" that is used for additional support

- Crown Box Facade:

- One 48-inch x 12-inch x 0.75-inch board (Front)

- Two 12-inch x 12.5-inch x 0.75-inch boards (Left & Right Sides)

- Mantle:

- One 55-inch x 16-inch x 0.75-inch board (secured to the top of the Crown Box)

- Miscellaneous:

- 8 x plastic feet (for the bottom of the base box)

- 1 gallon of white semi-gloss paint (for the boxes and mantel)

- 1 can of flat gray spray primer (for the backing board)

- 1 can of rough-textured gray spray paint (for the backing board)

Creating the Grate

I could have bought an actual fireplace grate upon which to rest the fake fireplace logs, but those are usually made from wrought iron because they need to stand up to the heat of an actual fire. Using a real grate would also add a bunch of unnecessary weight to the overall project, and storing the grate would be a pain. With that in mind, I decided to create my own out of PVC pipe because it would be considerably lighter, and it afforded me the option to disassemble grate for storage later.

I chose to use 1.5-inch PVC pipe to construct the grate, and here is the list of parts for that part of the project:

- Lots of measured PVC cuts:

- 36 x 1.5-inch (for joining crosses/elbows and caps)

- 7 x 4.5-inch (between the front and back halves)

- 8 x 4-inch (for the legs)

- PVC connectors:

- 18 x 90-degree elbows

- 14 x crosses

- 10 x caps (three on the front and back, two on the right and left sides)

- Miscellaneous:

- PVC cement

- 8 x 1.5-inch rubber feet (for the bottom of the legs)

- I can of flat black spray paint

It took me a long time to cut all of the PVC pipe, and I had enough materials for me to cut a few different lengths for the legs in order to see what the grate looked like at a few different heights. In the end I decided on a 4-inch height for the legs - this seemed to look the best to me. Once I had everything cut, I assembled it just to make sure that everything was going to fit together, then I disassembled it and used the PVC cement to secure the parts of the construction that I didn't want slipping over time (like the legs). Once I reassembled the grate and painted it, I could still disassemble several parts of the grate if I wanted to do so, but I'll probably store the grate intact just to keep the parts together.

Official Unveiling

Despite having worked the entire construction weekend, I still wasn't quite done when Kathleen was due home, so I assembled what I had without bolting everything together. (I still had some final painting to do, and I had some decorative trim that I was still considering for the project.) Just the same, it was far enough along that I could put all of the pieces together and surprise Kathleen when she arrived. She unwittingly gave me a great compliment when asked where I had bought the fireplace. ;-]

Still, I had some work left to do and some changes that I wanted to make - so after leaving the fireplace set up for a week or so, I disassembled it, changed out some of the wood, repainted everything with several additional coats of paint, and I reassembled it.

Here's what the completed project looks like:

This was a great project to build, and it's always fun to work on a project with my dad. But the most important result was - of course - that Kathleen now has a place to hang her Christmas stockings. ;-]